week9. Molding and Casting#

- Author : jun kawahara / Kai Naito / Asako Okazaki (Fablab Kamakura)

- Date created : 03/01/2019

- modified: 05/05/2020

- modified: 04/01/2021 for the 2021 cycle

- modified: 03/23/2022 for the 2022 cycle (Toshiki Tsuchiyama)

Assignments#

refer to Assessment(2022) page - Molding and Casting

- Group assignment:

- Review the safety data sheets for each of your molding and casting materials

- Make and compare test casts with each of them

- Individual assignment:

- Design a 3D mould around the stock and tooling that you’ll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts.

Learning outcomes#

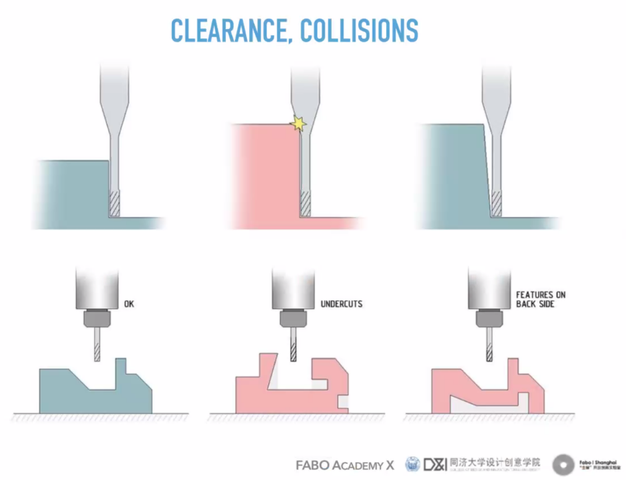

- Design appropriate objects within the limitations of 3 axis machining

- Demonstrate workflows used in mould design, construction and casting

Have you answered these questions?#

- Linked to the group assignment page and reflected on your individual page what you have learned

- Reviewed the safety data sheets for each of your molding and casting materials, then made and compared test casts with each of them

- Documented how you designed your 3D mould and created your rough and finish toolpaths for machining, including machine settings

- Shown how you made your mould and cast the parts

- Described problems and how you fixed them

- Included your design files and ‘hero shot’ of the mould and the final object

FAQ#

-

Should I mill a mould for the group assignment?

Answer: No, group assignment is for you to get familiar with the materials and the processes.

-

Should I read the MSDS and TDS this week?

Answer: Yes, always. Document the main points.

-

I want to only make a wax mould, and cast something in it. Is that acceptable?

Answer: Yes, if the parts you need to cast are soft.

-

What does 3-axis milling mean?

Answer: YYou should have smooth tilted or curved surfaces instead of “steps” towards axis Z.

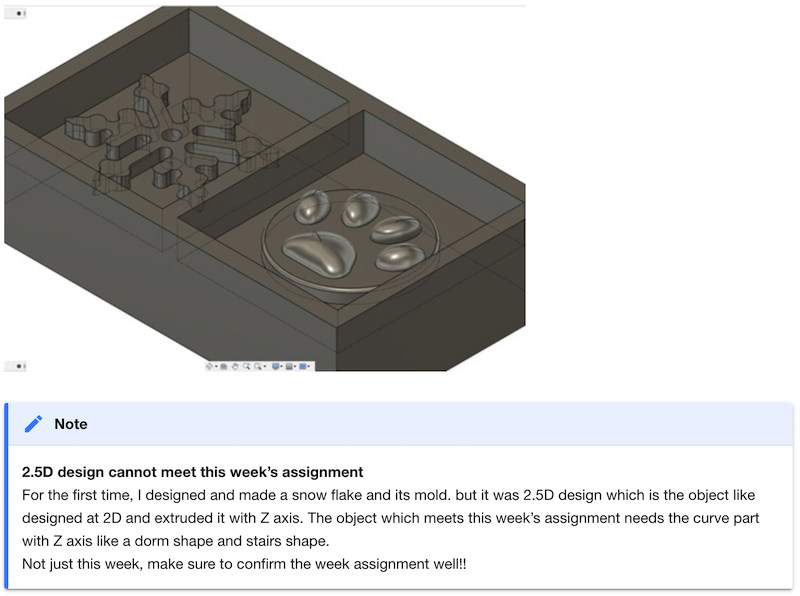

(image source: Kazuki Yanome/Kamakura)

(image source: Kazuki Yanome/Kamakura) -

Can I 3D print the mold? Can I do a lasercut?

Answer: No, for this assignment you must mill the mould using a CNC milling machine. After fulfilling the requirements, please go ahead and experiment other techniques for fabricating moulds.

Individual Assignment#

Step 1 - Design a mold#

- stock size

- Ferris File-A-Wax Blue

- approx. size : 5-¾” x 3-½” x 1-⅜“(146 x 88 x 35 mm)

-

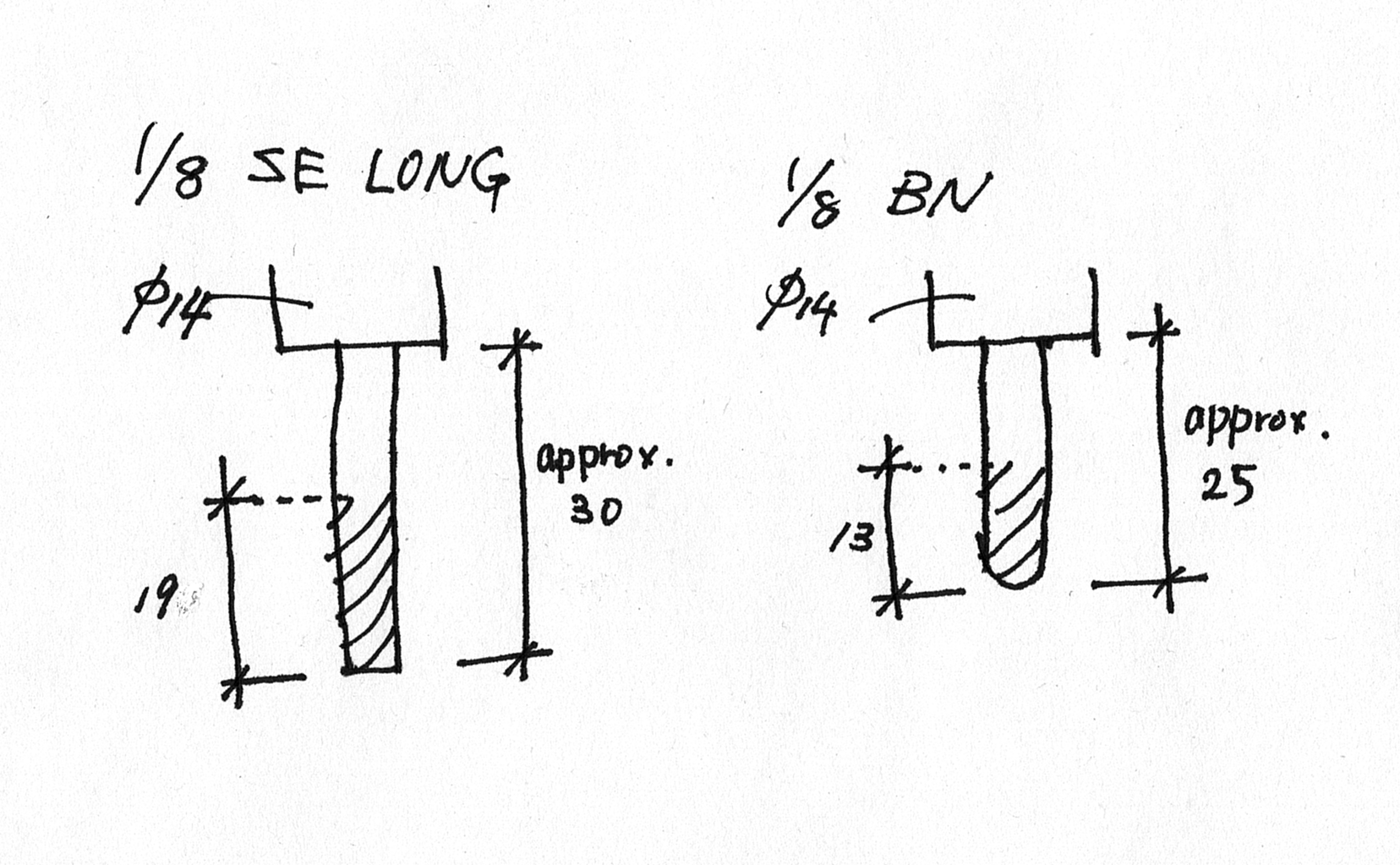

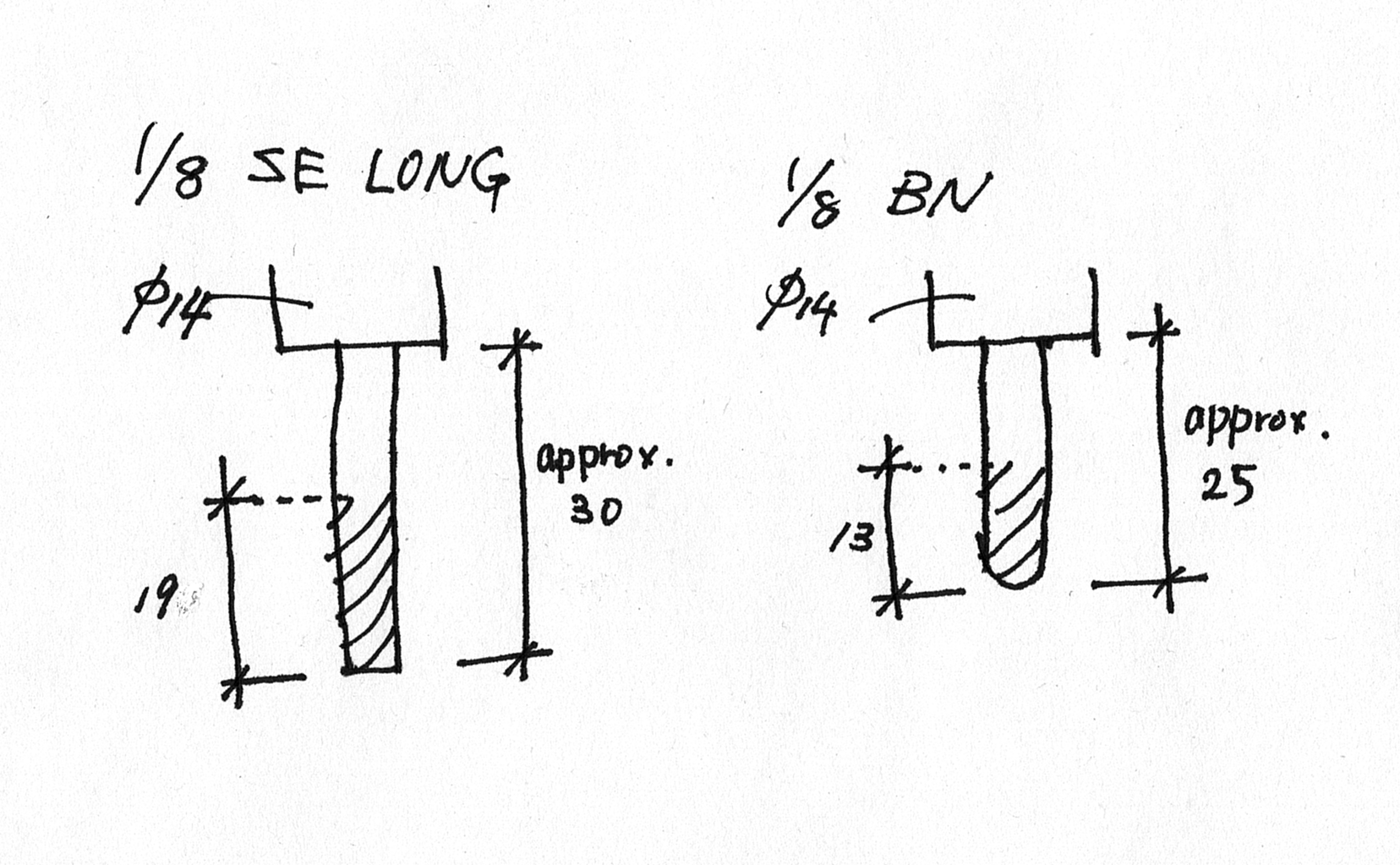

Tools

- ⅛inch (3.18 mm) long 4FL SE

- ⅛inch 2FL BN

- 1/16inch 2FL BN

-

how to design a mold

- Molding & Casting Week - Mold Making Tutorial in Fusion360 - Tutorial by Rico-san

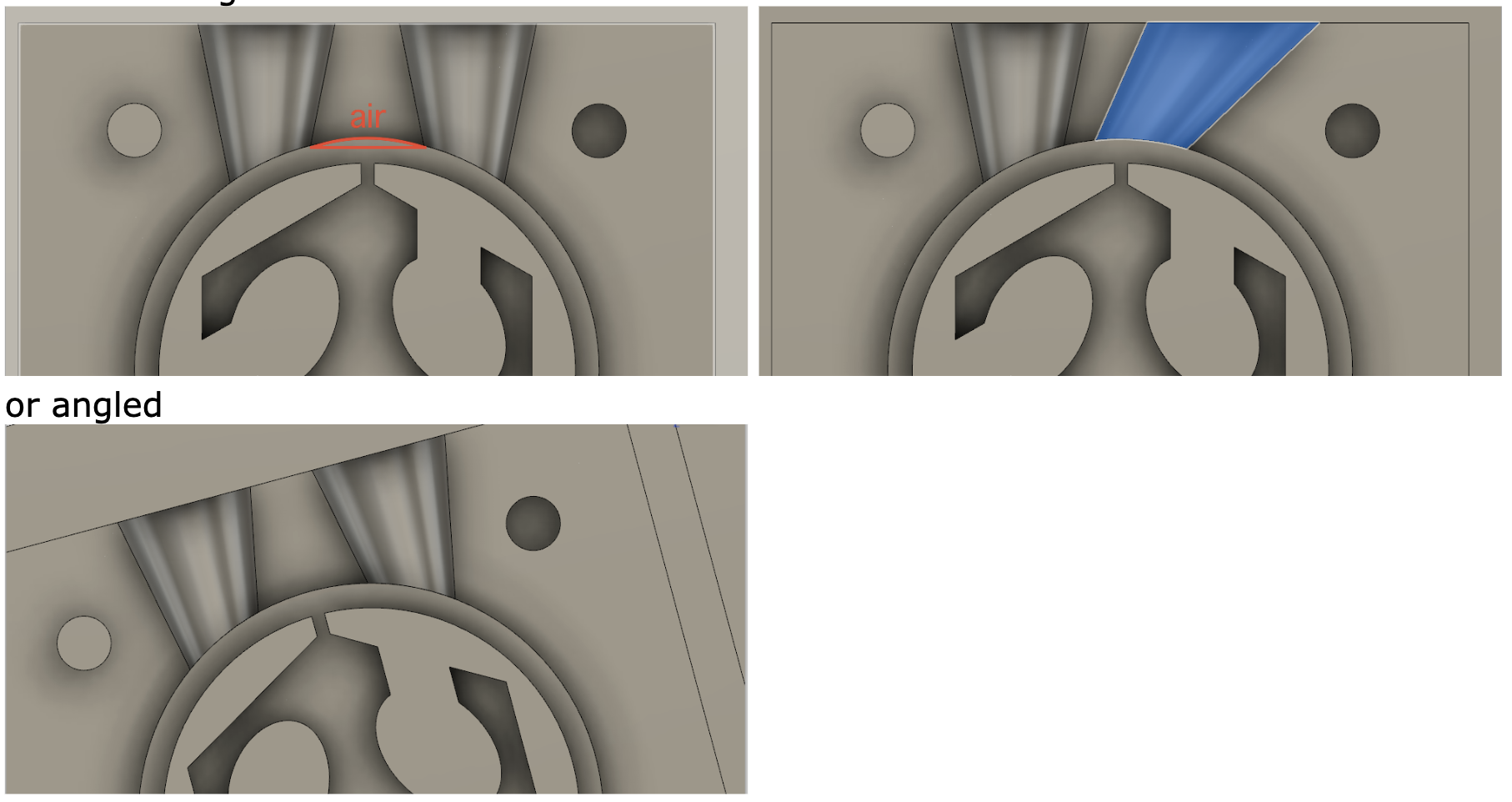

- vents for pouring a material and ventilating air bubbles should be taken into account in your desing.

(image source: Yuichi Tamiya / Kannai)

(image source: Yuichi Tamiya / Kannai)

Step 2 - mill it (rough cut + (at least) three-axis finish cut)#

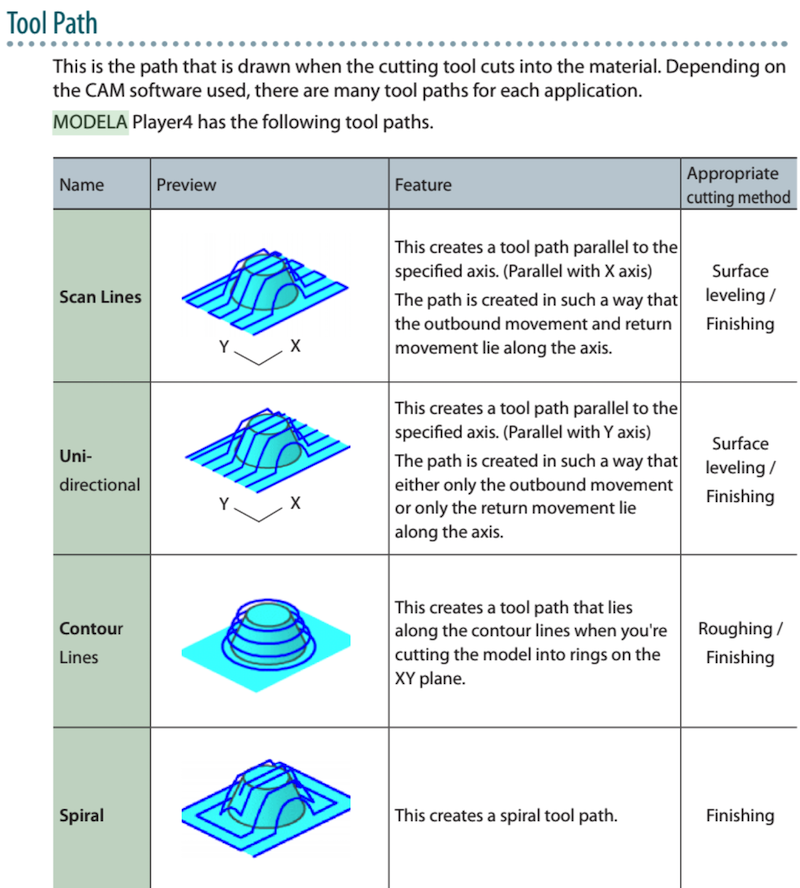

Before milling, you have to make toolpaths for roughing and finishing.

- machine: SRM-20

- CAM: MODELA Player 4

- roughing: Roughing toolpath is used to remove the large amount of the stock material quickly

- finishing: Finishing toolpath is used to remove a small amount of material, and to give the part the nicer surface

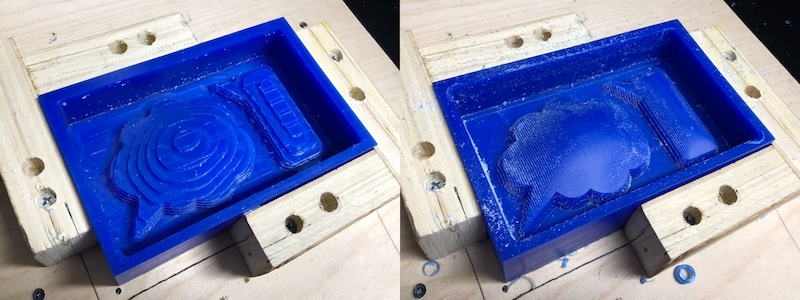

(image source: Flavie Liu / O Shanghai)

(image source: Flavie Liu / O Shanghai) - A CAM software, MODELA Player 4 has the following toolpaths. Past students in Kamakura basicaclly use Contour Lines in roughing, and Contour or Scan Lines in finishing.

(immage sourde: SRM-20 User’s Manual)

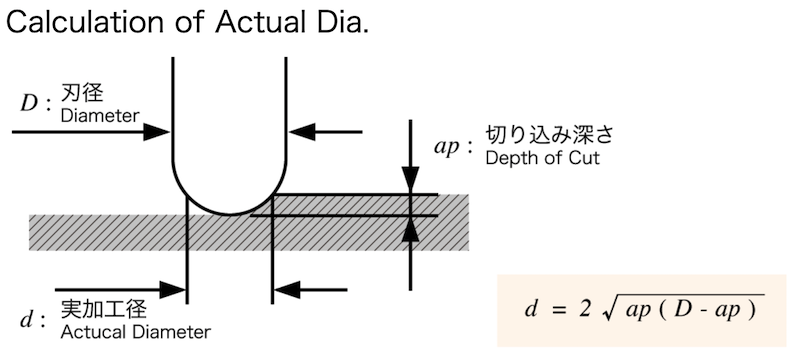

(immage sourde: SRM-20 User’s Manual) - Tools

- Square End:can be used for both roughing and finising.

- Ball (Nose) End:used for milling contoured surfaces

(image source: NS TOOL)

(image source: NS TOOL) - Xtra Long : Longer tool lengths for deep pocket. Runout increases with cutting tool length. Be careful that the endmill shank or spindle collet don’t collide with the stock material.

Step 3 - Use it to cast parts#

Read Safety Data Sheet(SDS) / Technicacl Data Sheet(TDS) before using it. Wear protective gears based on SDS. Please read How to read a Safety Data Sheet (SDS), for beginners.

-

Smooth-On Document Library - Technical Bulletins (TB), Safety Data Sheets (SDS)

- MOLD STAR 16 FAST

- SMOOTH-CAST 300

- SMOOTH-CAST 325

-

- TB / SDS / Food Safe Technical Bulletin

- Color: Water Clear Translucent

- Pot Life: 25 minutes

- Cure Time: 4 hours

- Mix Ratio By Volume: 1A:1B

- Mix Ratio By Weight: 1A:1B

-

How to avoid bubbles in the casting

- stirring : Two-part materials have to be mixed thoroughly, otherwise they will not be cured uniformly. You have to mix them completely, but try to avoid the air bubbles trapped in the material.

- pot life : Although you have to mix completely, each material has its pot life, a shorter one is a few minutes, a longer one is half an hour. Check its pot life before using it.

- pouring : Slowly pour into the one corner of the mold

- painting : Apply mold material to the model surface. More is not better. Thin layers work best, especially for the first layer or “detail coat.”

- vacuum degassing - not available in the Lab

- Doxy 5 Vacuum De-Gassing Agent

- rotation molding

- stirring : Two-part materials have to be mixed thoroughly, otherwise they will not be cured uniformly. You have to mix them completely, but try to avoid the air bubbles trapped in the material.

group assignment#

-

How to read a Safety Data Sheet (SDS), for beginners - MIT/CBA

Most critical sections:

As you can see, there is valuable information in each section. However, while any user should always read the entire SDS, the most critical information for your health and safety can be found in:

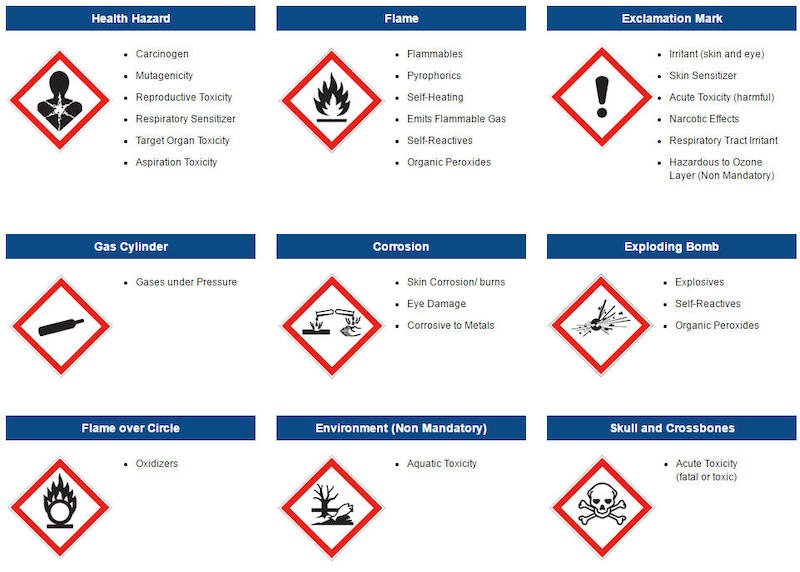

Section 2: Hazard identification

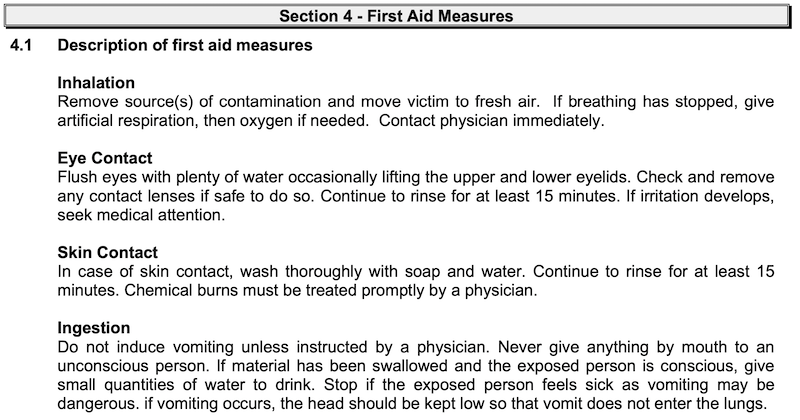

Section 4: First aid measures

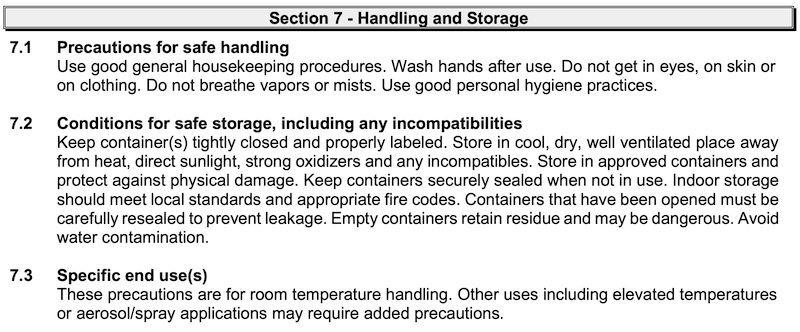

Section 7: Handling and storage

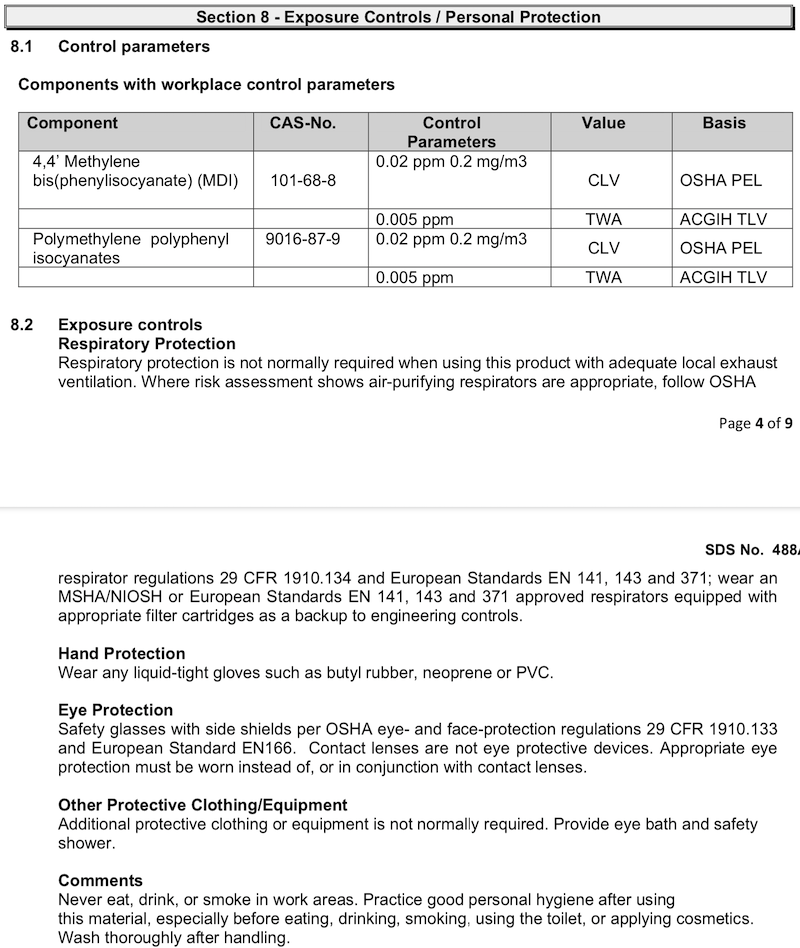

Section 8: Exposure controls/personal protection -

GHS hazard pictograms

(image source: SETON)

(image source: SETON)

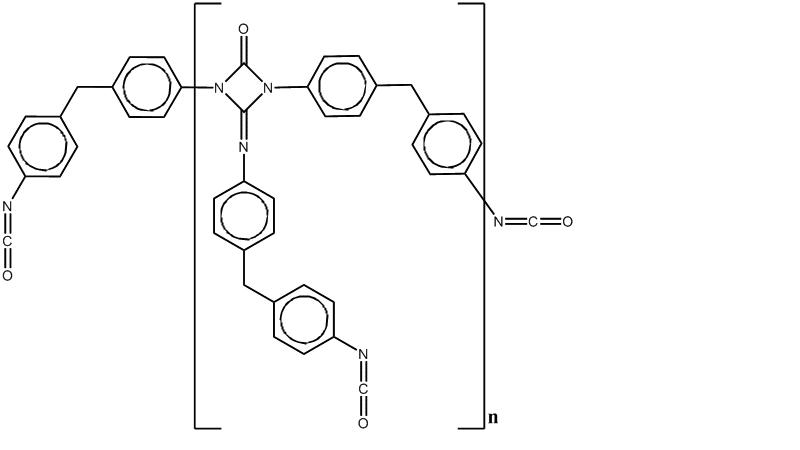

excerpt from Smooth-Cast 300 SDS#

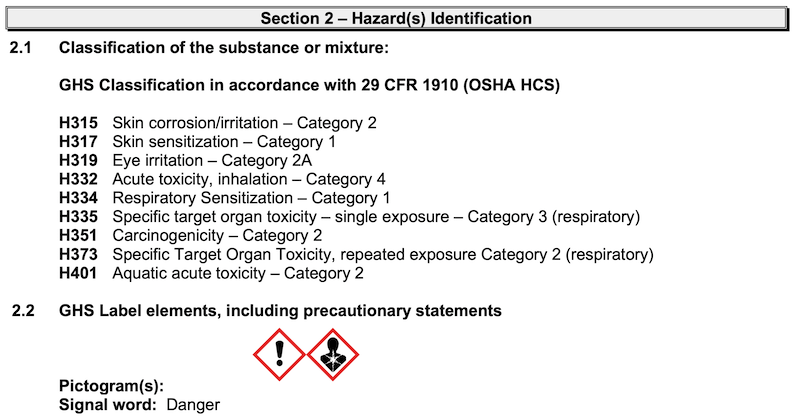

Section 2: Hazard identification#

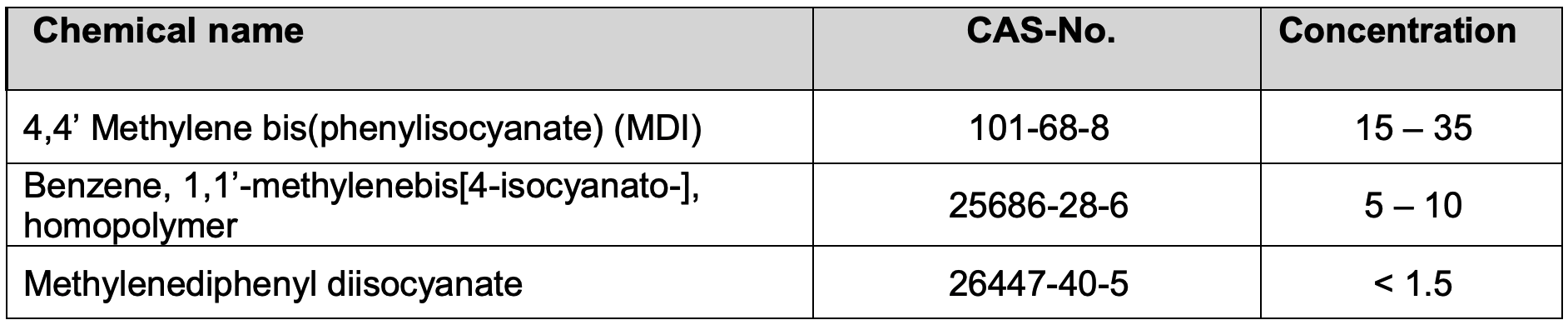

Section 3: Composition / Information of ingredients#

Smooth-Cast 300 consists of Part A and B.

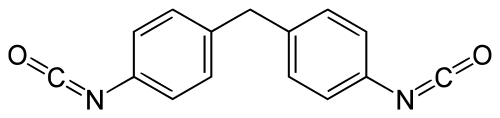

Ingredients of Part A are isocyanates.

If you want to know what its structure looks like, google it using CAS number like, “CAS:101-68-8“

4,4 Methylene bis(phenylisocyanate)(MDI)

Benzene, 1,1’-methylenebis[4-isosyanato-], homopolymer

Ingredients of Part B is disclosed in SDS, but it must be polyols, which is containing a bunch of -OH group.

Section 4: First aid measures#

Section 7: Handling and storage#

Section 8: Exposure controls/personal protection#

Announcements#

- Apr 19 recitation: fab ecosystem

references#

- SRM-20 User’s Manual

- 3D CAM Toolpath Fundamentals - CNC COOKBOOK

- How to read a Safety Data Sheet (SDS), for beginners - MIT/CBA

- Why are there bubbles on the surface of my rubber mold? - Smooth-on